1944

Where it all began

Founded in Alcobaça, producing crystal chandeliers and glassware.

1945

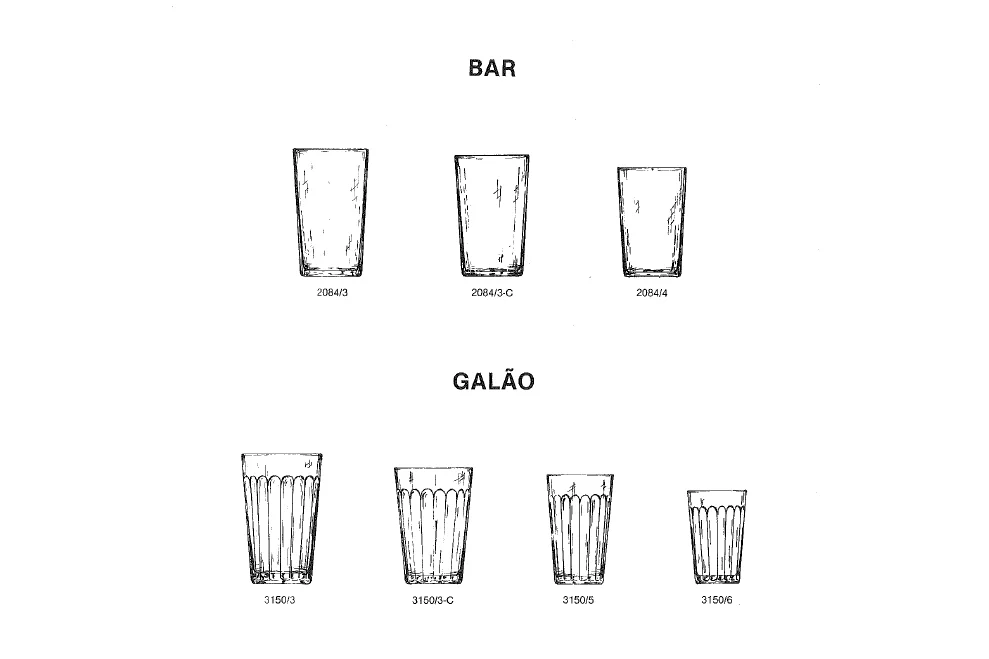

First Iconic Products

The Bar and Galão glasses are produced. They would later become symbols of Portuguese popular culture and the first to be automated.

1970

National Expansion

Relocated to Marinha Grande; automated production starts, launching the ‘Crisal Glass’ brand.

1977

First Commercial Ranges

Launch of the first glassware collections: Crisal and Mónica.

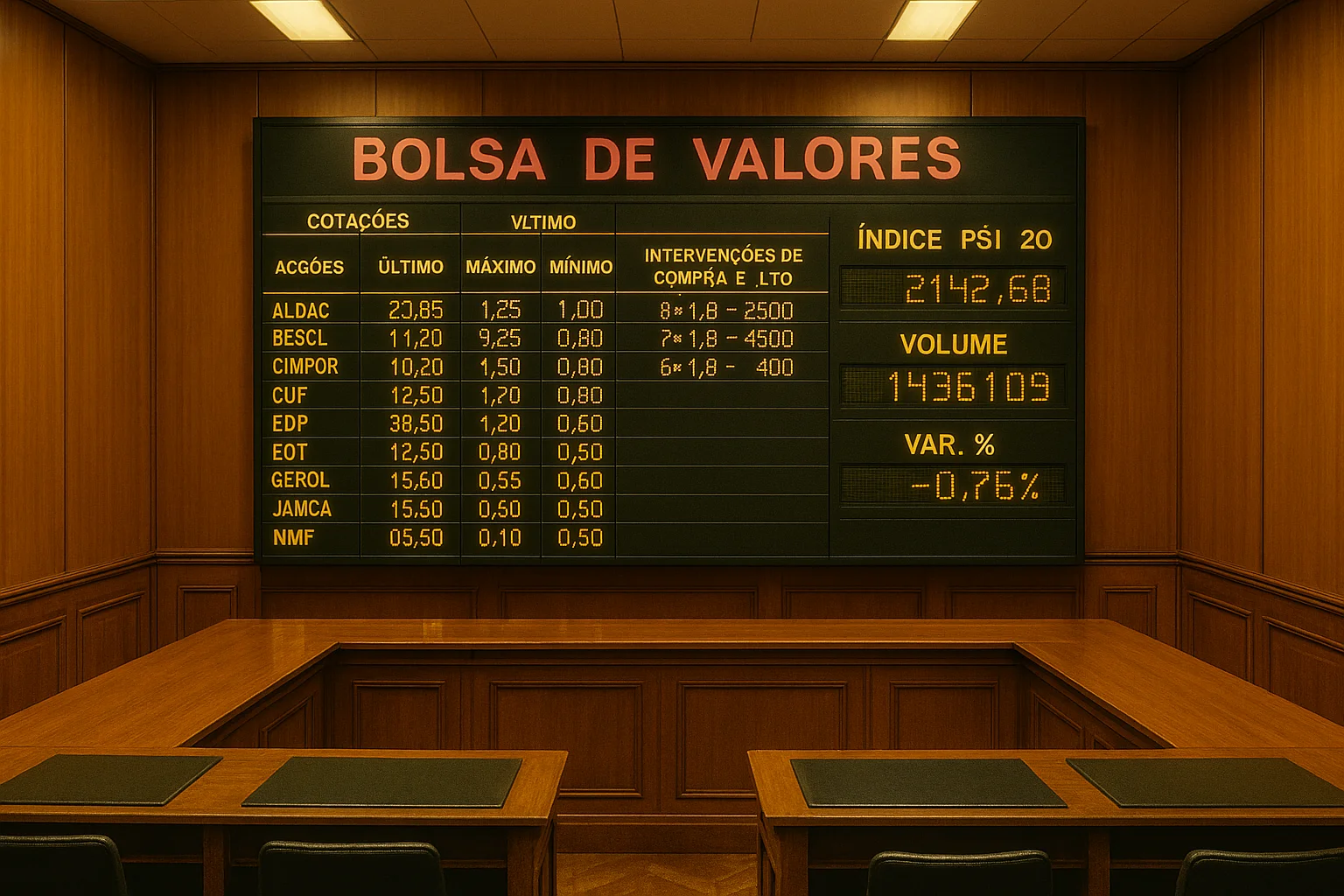

1986

Stock Market Debut

Listed on the stock exchange as ‘CRISAL – Cristais de Alcobaça, SA’.

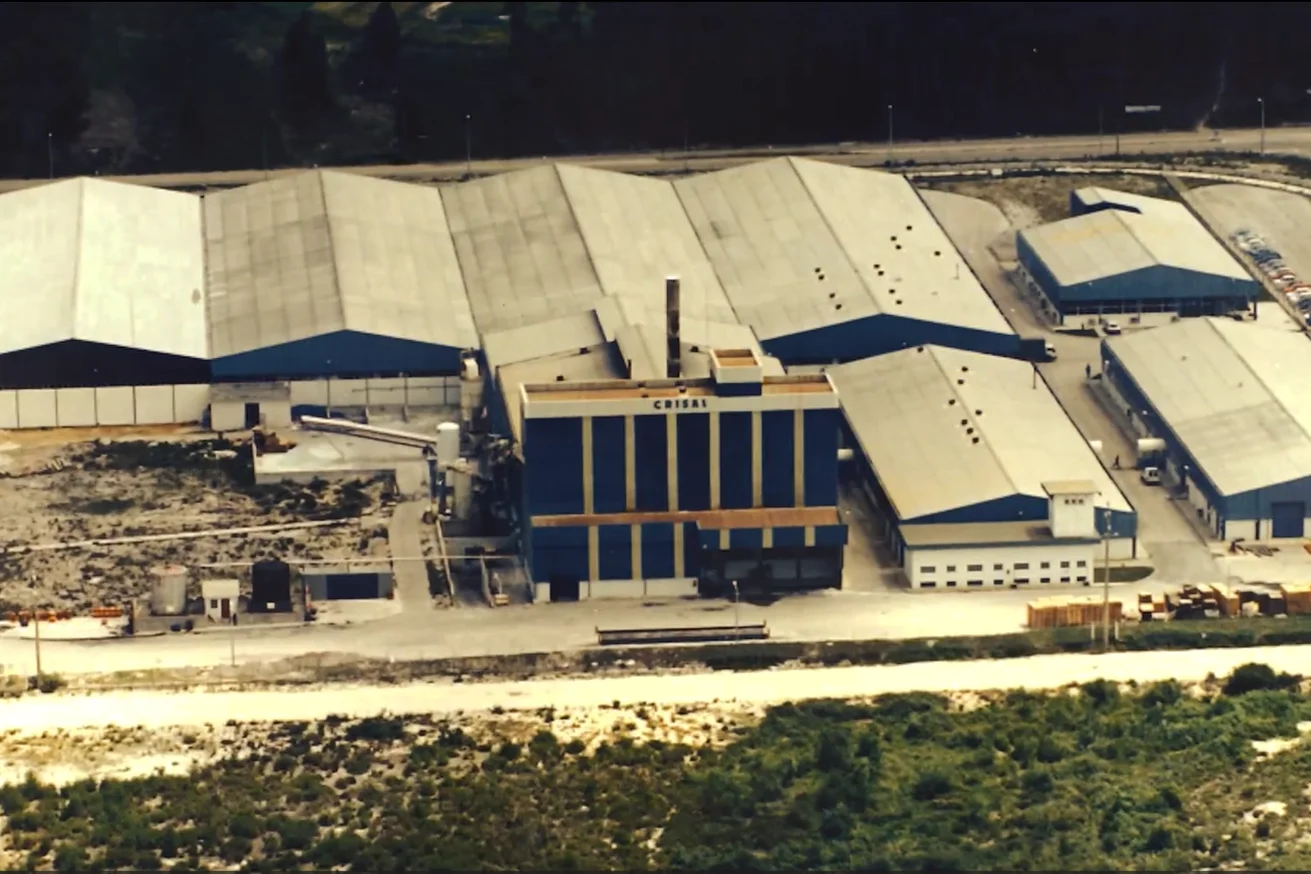

1987

New Factory in Marinha Grande

A new 18,000 m² plant was built in Casal da Lebre, Lote 1, Marinha Grande.

1989

Large-Scale Production

Large-scale production starts operating one furnace feeding three press lines and one blown line. Launch of the ONIS brand for the Retail market.

1993

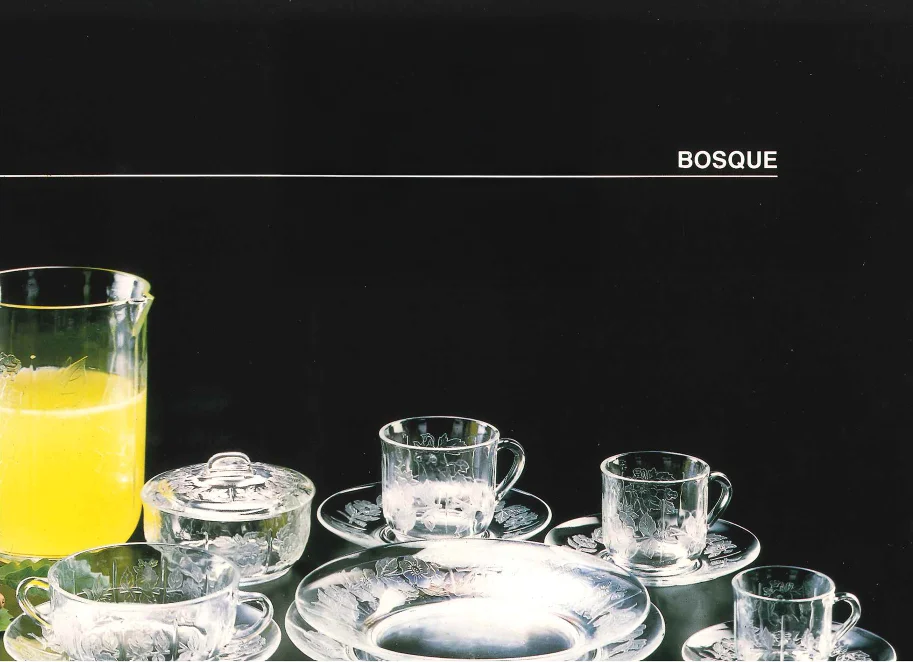

Bosque Collection

Launch of the iconic Bosque collection, the most complete in CRISAL’s history.

1996

A Year of Transformation and Innovation at CRISAL

First factory in Portugal to adopt natural gas for production.

Natural gas powers new Furnace 2.

ISO 9001 certification.

Launch of the Crisal Glass brand.

1998

Capacity Expansion

Two furnaces in operation with five production lines.

1999

Foundation of Printglass

A decoration company established within CRISAL’s facilities, dedicated exclusively to the brand.

2001

Merger with Vista Alegre

New designation: "CRISAL - Automatic Glassware, SA."

2005

Integration into Libbey Group

Crisal is acquired by Libbey Inc., joining international brands such as Crisa (Mexico), Royal Leerdam (Netherlands), and Libbey China.

2006-2012

Sustainable Transformation

Implementation of the LE technology.

Installation of an electrostatic precipitator to reduce dust emissions.

New pressing technology.

Investment in a wastewater treatment plant.

2016

Xtratuff® Process

Introduction of a special heat treatment that increases the strength of pressed glasses.

2022

New European Era

Anders Invest acquires CRISAL and Royal Leerdam, forming the

Leerdam Crisal Glass group focused on innovation and sustainability.

2022–2023

ONIS Returns

The historic ONIS brand is reinvented with a focus on Foodservice market and bar professionals.

2023

Commitment to Decarbonization

CRISAL and REGA ENERGY sign a longterm agreement for the supply of renewable gases.

2024 october

CRISAL invests in a sustainable future

CRISAL invests its own capital and PRR funds in measures to reduce environmental impact and accelerate energy transition.

2024 december

Construction of an Oxyhybrid Furnace

Construction of a state-of-the-art furnace, with hybrid oxy-fuel technology, which allows higher efficiency and lower carbon emissions.

2025 - february

Green Energy transition

Conclusion of the installation of a photovoltaic self-production unit.

2025 - July

ISO 50001 Certification

To improve energy efficiency and decarbonization, reinforcing our commitment to sustainability.